Professional UK-Based Exporter of Quality Brake Pads Worldwide

As a leading UK-based exporter of quality brake pads, we specialize in supplying premium automotive safety components across European markets. Our extensive inventory includes high-performance ceramic brake pads, durable metallic brake pads, and efficient low-metallic formulations designed for various driving conditions. Each product undergoes rigorous quality testing to ensure optimal stopping power, reduced noise levels, and extended service life. We export to over 30 countries with reliable shipping and customs documentation handled efficiently. Our technical support team provides comprehensive guidance on product selection and installation procedures. Trust our two decades of industry experience for all your automotive brake system requirements and safety needs.

Ceramic Brake Pads Designed for High-Performance Automotive Safety Standards

Our ceramic brake pads designed for high-performance automotive safety deliver exceptional stopping power in demanding driving conditions. These advanced friction materials combine ceramic compounds with copper fibers to provide smooth, quiet operation with minimal dust production. The unique formulation ensures consistent braking performance across temperature variations while protecting rotors from excessive wear. These premium brake pads offer superior heat dissipation properties that prevent brake fade during aggressive driving. Installation is straightforward with proper bedding-in procedures outlined in our comprehensive guides. Customers report significantly improved pedal feel and reduced stopping distances. These ceramic formulations represent the pinnacle of braking technology for modern vehicles.

Metallic Brake Pads for Heavy-Duty Commercial Vehicles and Towing

Our metallic brake pads provide exceptional durability and stopping power for heavy-duty commercial vehicles, towing applications, and high-performance driving. Constructed with up to 70% metal content including steel, copper, and iron alloys, these robust pads deliver consistent performance under extreme conditions. The advanced compound formulation ensures optimal friction characteristics while withstanding intense heat generated during aggressive braking. These metallic brake pads excel in commercial fleets, delivery vehicles, and performance cars where braking demands exceed standard requirements. Proper installation following our detailed guidelines ensures maximum performance and service life. Many professional mechanics recommend our metallic formulations for their reliability and consistent performance across diverse operating conditions.

Low Metallic Brake Pads Offering Quiet Operation with Enhanced Stopping

Our low metallic brake pads strike the perfect balance between performance, noise reduction, and rotor compatibility. Containing approximately 30% metal content blended with organic materials, these advanced formulations provide strong initial bite without excessive noise or dust. The sophisticated compound delivers reliable braking performance in daily driving conditions while maintaining rotor integrity. These low metallic brake pads undergo extensive testing to ensure consistent friction coefficients and smooth operation. Installation follows standard procedures with proper bedding-in recommended for optimal performance. Many European vehicle owners prefer these pads for their balanced characteristics and minimal brake dust production. Our technical team provides comprehensive support for proper selection and installation.

Premium Spark Plugs Optimized for Fuel Efficiency and Engine Performance

Our premium spark plugs deliver optimal ignition performance, improved fuel efficiency, and smoother engine operation across various driving conditions. Manufactured with advanced electrode materials including iridium and platinum, these high-quality components ensure consistent spark energy and extended service intervals. The precise engineering maintains proper heat range characteristics for efficient combustion in both standard and high-performance engines. Proper installation following torque specifications and gap adjustments ensures maximum performance benefits. Many automotive technicians recommend our spark plugs for their reliability and consistent operation in diverse climate conditions. Our comprehensive product range includes options for classic vehicles, modern direct injection engines, and high-performance applications with specific heat range requirements.

Exporting Quality Automotive Brake Components from UK to Global Markets

We specialize in exporting quality automotive brake components from our UK manufacturing facilities to global markets with comprehensive logistics support. Our extensive distribution network ensures timely delivery to automotive retailers, repair shops, and wholesale distributors across Europe, Asia, and North America. Each shipment includes complete documentation, quality certifications, and compliance paperwork for smooth customs clearance. Our product range includes ceramic brake pads, metallic formulations, low-metallic options, and premium spark plugs engineered for various vehicle applications. Technical support is available in multiple languages with detailed product information and application guides. Our quality management system ensures consistent product performance and customer satisfaction across international markets.

Advanced Ceramic Brake Pad Technology for Superior Automotive Safety

Our advanced ceramic brake pad technology represents the pinnacle of automotive safety innovation with sophisticated material science and engineering. These premium brake pads incorporate specialized ceramic compounds reinforced with copper fibers for optimal thermal management and consistent friction characteristics. The unique formulation minimizes brake dust while providing smooth, quiet operation across diverse driving conditions. Extensive testing validates performance metrics including fade resistance, wear characteristics, and stopping distances. Professional installers appreciate the straightforward installation process and compatibility with various rotor materials. These ceramic brake pads designed for high-performance automotive safety meet or exceed OEM specifications for numerous vehicle models. Customer feedback consistently highlights improved braking responsiveness and reduced maintenance requirements.

Heavy-Duty Metallic Brake Pads for Commercial Fleet Applications

Our heavy-duty metallic brake pads deliver exceptional performance for commercial fleet applications, towing vehicles, and severe service conditions. The high-metal-content formulation provides consistent braking power even under extreme temperature conditions encountered in mountainous terrain or stop-and-go urban delivery routes. These robust metallic brake pads undergo rigorous testing for fade resistance, wear characteristics, and noise vibration harshness performance. Professional fleet managers appreciate the extended service intervals and reduced maintenance costs associated with our premium formulations. Proper installation following our technical guidelines ensures optimal performance and safety compliance. Many transportation companies standardize on our metallic brake pads for their reliability and consistent performance across diverse vehicle types and operating conditions.

Optimized Low Metallic Brake Pads for Daily Driving Comfort

Our optimized low metallic brake pads provide the perfect combination of performance and comfort for daily driving applications. The sophisticated compound blends metallic fibers with organic materials to deliver strong initial bite without excessive noise or dust production. These advanced low metallic brake pads undergo extensive development to ensure compatibility with various rotor materials and vehicle systems. The formulation provides consistent braking performance across temperature variations while maintaining rotor integrity. Installation follows standard procedures with proper bedding-in recommended for optimal performance. Many vehicle owners prefer these pads for their balanced characteristics and minimal maintenance requirements. Our technical support team provides comprehensive guidance on proper selection and installation techniques.

High-Performance Spark Plugs for Enhanced Engine Efficiency

Our high-performance spark plugs deliver optimal ignition characteristics for improved engine efficiency, smoother operation, and reduced emissions. The advanced electrode design featuring fine-wire iridium or platinum tips ensures consistent spark energy and extended service life. These premium components maintain proper heat range characteristics for efficient combustion across various driving conditions and fuel types. Professional technicians appreciate the reliable performance and easy installation of our comprehensive spark plug range. Proper gapping and torque specifications ensure maximum benefits including improved throttle response and fuel economy. Many automotive enthusiasts choose our spark plugs for their consistent performance in both standard and modified engines. Our technical documentation provides detailed application information and installation guidelines.

International Export Procedures for UK Automotive Brake Components

We streamline international export procedures for UK automotive brake components with comprehensive logistics support and documentation services. Our experienced team handles all aspects of international shipping including customs documentation, quality certifications, and compliance requirements for various markets. As a leading UK-based exporter of quality brake pads, we maintain established relationships with global logistics partners to ensure timely delivery. Our product range includes ceramic formulations, metallic brake pads, low-metallic options, and premium spark plugs engineered for diverse vehicle applications. Technical documentation is available in multiple languages with detailed application guides and installation procedures. Customers appreciate our responsive service and attention to detail in international trade compliance.

Quality Assurance Standards for Exported Automotive Brake Pads

Our rigorous quality assurance standards for exported automotive brake pads ensure consistent performance and reliability across global markets. Each production batch undergoes comprehensive testing for friction characteristics, wear resistance, noise performance, and structural integrity. As a leading UK-based exporter of quality brake pads, we maintain ISO 9001 certification with additional compliance to international automotive standards. Our metallic brake pads, ceramic formulations, and low-metallic options all meet or exceed OEM specifications for various vehicle applications. Detailed quality documentation accompanies each shipment with complete traceability and compliance certificates. Customers worldwide trust our products for their consistent performance and safety characteristics. Our technical team provides ongoing support for proper installation and application guidance.

Ceramic vs Metallic Brake Pads: Comprehensive Performance Comparison Guide

Understanding the differences between ceramic and metallic brake pads helps consumers make informed decisions based on their specific driving needs and vehicle requirements. Ceramic brake pads designed for high-performance automotive safety typically offer quieter operation, less dust production, and consistent performance across temperature ranges. Metallic brake pads generally provide stronger initial bite and better heat dissipation for demanding applications like towing or performance driving. Low metallic brake pads strike a balance between these characteristics with moderate metal content. Each type has distinct advantages depending on driving style, vehicle type, and performance expectations. Our technical team provides detailed guidance to help customers select the optimal brake pad type for their specific application and driving conditions.

Installation Guidelines for Premium Ceramic Brake Pad Systems

Proper installation guidelines for premium ceramic brake pad systems ensure optimal performance, safety, and service life. Begin by thoroughly cleaning the brake caliper assembly and inspecting components for wear or damage. Carefully lubricate appropriate contact points with high-temperature brake lubricant while avoiding contamination of friction surfaces. Follow torque specifications precisely when reinstalling calipers and related components. The bedding-in process is crucial for ceramic brake pads designed for high-performance automotive safety – gradually build heat through moderate braking from various speeds. Avoid aggressive braking during the first few hundred miles to allow proper transfer layer formation on rotors. Our detailed installation manuals provide vehicle-specific instructions and technical support is available for professional installers.

Heat Management Properties of Advanced Metallic Brake Pads

The exceptional heat management properties of advanced metallic brake pads make them ideal for demanding driving conditions and heavy-duty applications. The high metal content, typically 60-70% steel, copper, and iron alloys, provides superior thermal conductivity that dissipates heat quickly from the friction surface. This characteristic reduces the risk of brake fade during repeated hard stops or prolonged downhill braking. Metallic brake pads maintain more consistent friction characteristics at elevated temperatures compared to organic alternatives. The robust construction withstands thermal stress without cracking or degradation. Professional drivers appreciate these thermal management properties for towing, mountain driving, and performance applications. Our technical data sheets provide detailed information on temperature performance ranges and application guidelines.

Noise Reduction Technology in Modern Low Metallic Brake Pads

Advanced noise reduction technology in modern low metallic brake pads ensures quiet operation while maintaining strong braking performance. These sophisticated formulations incorporate specialized shims, chamfers, and slot designs that disrupt harmonic frequencies causing brake noise. The optimized compound blends metallic fibers with noise-dampening materials to minimize vibration transmission. Extensive NVH testing validates the effectiveness of these design features across various operating conditions. Low metallic brake pads from our UK manufacturing facilities incorporate these technologies while delivering reliable stopping power. Professional installers appreciate the straightforward installation and consistent performance. Many vehicle owners report significantly reduced brake noise compared to standard formulations. Our technical team provides comprehensive support for proper installation and troubleshooting.

Selection Criteria for Optimal Spark Plug Performance and Longevity

Proper selection criteria for optimal spark plug performance and longevity consider multiple factors including heat range, electrode design, and specific engine requirements. The heat range must match engine operating characteristics to prevent fouling or pre-ignition issues. Modern iridium and platinum spark plugs offer extended service intervals and consistent performance across diverse operating conditions. Vehicle-specific considerations include ignition system type, fuel quality, and typical driving patterns. Our comprehensive product range includes options for standard passenger vehicles, high-performance applications, and specialized engines. Technical documentation provides detailed application information and installation guidelines. Many professional technicians recommend our spark plugs for their reliable performance and extended service life. Proper installation following torque specifications ensures optimal operation.

Global Distribution Network for UK-Exported Automotive Brake Components

Our extensive global distribution network for UK-exported automotive brake components ensures reliable delivery to markets worldwide. Strategic partnerships with international logistics providers enable efficient shipping to Europe, North America, Asia, and emerging markets. As a leading UK-based exporter of quality brake pads, we maintain inventory levels to meet demand fluctuations and seasonal variations. Our distribution centers implement sophisticated inventory management systems with real-time stock visibility. Customers benefit from consolidated shipping options and comprehensive documentation services. The product range includes ceramic formulations, metallic brake pads, low-metallic options, and premium spark plugs for various vehicle applications. Regional technical support provides application guidance and product information in local languages.

Performance Testing Protocols for Automotive Brake Pad Safety

Rigorous performance testing protocols for automotive brake pad safety validate product reliability and compliance with international standards. Our testing procedures evaluate multiple parameters including friction consistency, fade resistance, recovery characteristics, and wear rates under various conditions. Ceramic brake pads designed for high-performance automotive safety undergo additional testing for noise vibration harshness and rotor compatibility. Metallic formulations are tested for extreme temperature performance and structural integrity. Low metallic brake pads are evaluated for balanced characteristics across diverse operating conditions. All testing follows standardized procedures with documentation available for professional customers. Our quality management system ensures consistent product performance and safety compliance. Technical data sheets provide detailed performance metrics for professional installers and fleet managers.

Commercial Vehicle Applications for Heavy-Duty Metallic Brake Pads

Specialized commercial vehicle applications for heavy-duty metallic brake pads address the unique demands of fleet operations, towing, and severe service conditions. These robust formulations deliver consistent braking performance under extreme load and temperature conditions encountered in commercial operations. The high metal content provides excellent heat dissipation and fade resistance during prolonged braking. Metallic brake pads for commercial applications undergo additional testing for durability and performance consistency. Fleet managers appreciate the extended service intervals and reduced maintenance costs. Proper installation following our technical guidelines ensures optimal performance and safety compliance. Many transportation companies standardize on our metallic formulations for their reliability across diverse vehicle types and operating conditions. Our technical team provides comprehensive support for fleet applications.

European Market Compliance for UK-Exported Brake Components

Comprehensive European market compliance for UK-exported brake components ensures adherence to regulatory requirements and technical standards. Our products meet ECE R90 regulations with complete documentation and certification for all European markets. As a leading UK-based exporter of quality brake pads, we maintain ongoing compliance with evolving regulatory requirements. The product range includes ceramic formulations, metallic brake pads, and low-metallic options with complete technical documentation. Shipping procedures include all required customs documentation and compliance certificates. Our quality management system ensures consistent product performance and regulatory compliance. Customers across European markets trust our products for their reliability and adherence to technical standards. Regional technical support provides additional guidance on application and installation requirements.

Technical Specifications for Premium Automotive Spark Plugs

Detailed technical specifications for premium automotive spark plugs provide essential information for proper selection and installation. Key parameters include heat range, thread size, reach, seat type, and electrode configuration. Our iridium and platinum spark plugs feature advanced electrode designs for optimal ignition performance and extended service life. Technical documentation specifies torque values, gap settings, and application information for various vehicle models. Professional technicians appreciate the comprehensive technical data for proper product selection and installation. Our spark plugs undergo rigorous testing for consistent performance across diverse operating conditions. Many automotive enthusiasts choose our products for their reliability in both standard and high-performance applications. Technical support is available for application-specific questions and installation guidance.

Environmental Considerations in Brake Pad Manufacturing and Export

Environmental considerations in brake pad manufacturing and export guide our operational practices and product development initiatives. We implement sustainable manufacturing processes with emphasis on resource efficiency and waste reduction. Our ceramic brake pads designed for high-performance automotive safety utilize copper-reduced formulations in compliance with evolving environmental regulations. Metallic brake pads incorporate recycled materials where possible without compromising performance. Packaging materials are optimized for minimal environmental impact while ensuring product protection during international shipping. As a leading UK-based exporter of quality brake pads, we continuously evaluate and improve our environmental performance. Customers appreciate our commitment to sustainability while maintaining product quality and performance standards. Our environmental management system ensures ongoing compliance and improvement.

Customer Support Services for International Brake Component Export

Comprehensive customer support services for international brake component export ensure smooth transactions and ongoing technical assistance. Our multilingual support team provides guidance on product selection, application specifics, and installation procedures. Documentation services include customs forms, certificates of conformity, and technical specifications for various markets. As a leading UK-based exporter of quality brake pads, we maintain responsive communication channels for international customers. Technical support is available for installation questions, performance issues, and application guidance. Our product range includes ceramic formulations, metallic brake pads, low-metallic options, and premium spark plugs with complete documentation. Customers appreciate our responsive service and attention to detail in international transactions. Regional representatives provide localized support in key markets.

Advanced Formulation Technologies in Modern Ceramic Brake Pads

Advanced formulation technologies in modern ceramic brake pads represent significant innovations in automotive safety and performance materials. These sophisticated compounds blend ceramic fibers with non-ferrous metal particles and proprietary binding agents to create friction materials with exceptional characteristics. Ceramic brake pads designed for high-performance automotive safety typically exhibit consistent friction coefficients across temperature ranges, excellent fade resistance, and minimal rotor wear. The manufacturing process involves precise control of material composition and curing parameters to ensure batch-to-batch consistency. Extensive testing validates performance metrics including noise characteristics, wear rates, and stopping distances. Professional installers appreciate the straightforward installation and reliable performance of our ceramic formulations. Technical documentation provides detailed application information and installation guidelines for various vehicle systems.

Vehicle-Specific Applications for Premium Metallic Brake Pads

Precise vehicle-specific applications for premium metallic brake pads ensure optimal performance and compatibility with various automotive systems. Our comprehensive product range includes formulations specifically engineered for European luxury vehicles, American trucks, Asian imports, and performance models. Metallic brake pads for heavy-duty applications feature enhanced thermal stability and fade resistance for towing and commercial use. Performance versions provide strong initial bite and consistent operation during aggressive driving. Each formulation undergoes vehicle-specific validation to ensure proper compatibility with brake systems, ABS functionality, and electronic stability control systems. Technical documentation provides detailed application information including bed-in procedures and torque specifications. Professional installers appreciate the reliable performance and vehicle-specific engineering of our metallic brake pad range.

Technical Advantages of Copper-Reduced Brake Pad Formulations

Significant technical advantages of copper-reduced brake pad formulations address environmental concerns while maintaining performance standards. These advanced compounds utilize alternative materials including synthetic graphite, ceramic fibers, and non-ferrous metal alloys to replace copper content. Extensive research and development ensure these formulations meet or exceed performance characteristics of traditional copper-containing brake pads. Ceramic brake pads designed for high-performance automotive safety lead this transition with sophisticated copper-free formulations. Testing validates consistent friction characteristics, wear rates, and noise performance. Environmental regulations increasingly mandate reduced copper content in brake formulations, and our products comply with these evolving requirements. Technical documentation provides detailed information on composition and performance characteristics for professional customers and regulators.

Export Documentation Requirements for International Brake Shipments

Comprehensive export documentation requirements for international brake shipments ensure smooth customs clearance and regulatory compliance. Essential documents include commercial invoices, packing lists, certificates of origin, and product compliance certifications. As a leading UK-based exporter of quality brake pads, we provide complete documentation packages tailored to specific destination country requirements. Ceramic formulations, metallic brake pads, and low-metallic options all include appropriate technical documentation and compliance certificates. Our experienced logistics team stays current with evolving international trade regulations and documentation requirements. Customers appreciate the thorough documentation that facilitates smooth customs processing and reduces shipping delays. Regional requirements vary, and our team provides guidance on specific documentation needs for various markets. Technical support is available for additional product information.

Performance Validation Testing for Automotive Spark Plugs

Rigorous performance validation testing for automotive spark plugs ensures reliable operation across diverse engine types and operating conditions. Our testing protocols evaluate ignition performance, heat range characteristics, fouling resistance, and service life under various conditions. Advanced spark plugs with iridium or platinum electrodes undergo additional testing for long-term durability and consistent performance. Testing equipment simulates real-world operating conditions including temperature extremes, fuel variations, and ignition system demands. Technical data sheets provide detailed performance metrics for professional technicians and enthusiasts. Proper installation following specified torque values and gap settings ensures optimal performance. Many professional mechanics recommend our spark plugs for their reliable operation and extended service intervals. Technical support is available for application-specific questions.

Global Supply Chain Management for Automotive Brake Components

Sophisticated global supply chain management for automotive brake components ensures reliable product availability and timely delivery to international markets. Our integrated approach coordinates raw material sourcing, manufacturing scheduling, inventory management, and distribution logistics. As a leading UK-based exporter of quality brake pads, we maintain strategic relationships with material suppliers and logistics partners worldwide. The product range includes ceramic formulations, metallic brake pads, low-metallic options, and premium spark plugs with comprehensive inventory visibility. Customers benefit from consistent product quality and reliable delivery schedules. Our supply chain systems accommodate seasonal fluctuations and market demand variations. Technical support and customer service teams coordinate closely with logistics partners to ensure smooth transactions and responsive service.

Brake System Compatibility Considerations for Various Pad Types

Essential brake system compatibility considerations for various pad types ensure optimal performance and safety across diverse vehicle applications. Ceramic brake pads designed for high-performance automotive safety typically work well with modern ABS and stability control systems, providing smooth operation and consistent feedback. Metallic formulations offer strong initial bite suitable for performance vehicles and heavy-duty applications but may generate more dust and noise. Low metallic brake pads strike a balance with moderate metal content for daily driving comfort. Vehicle-specific factors include caliper design, rotor material, and electronic brake system characteristics. Our technical team provides detailed guidance on proper pad selection for specific vehicle types and driving conditions. Compatibility testing validates performance across various brake system configurations and components.

Industry Certification Standards for Automotive Brake Components

Comprehensive industry certification standards for automotive brake components validate product quality, performance, and safety compliance. Our manufacturing facilities maintain ISO 9001 quality management certification with additional compliance to international automotive standards including ECE R90. Ceramic brake pads designed for high-performance automotive safety undergo additional validation testing for noise, vibration, and harshness characteristics. Metallic formulations are tested according to industry standards for fade resistance, wear characteristics, and structural integrity. Certification documentation accompanies each shipment with complete traceability and compliance records. Customers worldwide trust our certified products for their consistent performance and adherence to technical standards. Our quality management system ensures ongoing compliance with evolving industry requirements and customer expectations.

Technical Support Services for International Brake Customers

Comprehensive technical support services for international brake customers provide essential guidance on product selection, installation, and performance optimization. Our multilingual technical team offers assistance with application-specific questions, installation procedures, and troubleshooting. As a leading UK-based exporter of quality brake pads, we maintain extended support hours to accommodate various time zones. Technical documentation includes detailed installation guides, torque specifications, and bed-in procedures for various brake pad types. Customers appreciate the responsive support for both routine questions and complex technical issues. Regional technical representatives provide localized support in key markets with specific vehicle knowledge and application experience. Our commitment to customer support ensures proper product application and customer satisfaction across international markets.

Vehicle Performance Optimization with Premium Spark Plugs

Significant vehicle performance optimization with premium spark plugs delivers measurable improvements in engine efficiency, throttle response, and fuel economy. Advanced electrode designs featuring iridium or platinum tips provide consistent spark energy for complete combustion across various operating conditions. Proper heat range selection ensures optimal plug temperature for self-cleaning without pre-ignition issues. Our comprehensive spark plug range includes options for standard passenger vehicles, high-performance applications, and specialized engines. Technical documentation provides detailed application information and installation guidelines. Professional technicians appreciate the reliable performance and extended service intervals. Many automotive enthusiasts report improved engine smoothness and responsiveness after installing our premium spark plugs. Proper installation following specified procedures ensures maximum performance benefits.

International Logistics Coordination for Brake Component Export

Efficient international logistics coordination for brake component export ensures timely delivery and proper handling throughout the supply chain. Our experienced logistics team manages shipping arrangements, customs documentation, and carrier coordination for shipments to global markets. As a leading UK-based exporter of quality brake pads, we maintain relationships with multiple international carriers to optimize shipping costs and transit times. The product range includes ceramic formulations, metallic brake pads, low-metallic options, and premium spark plugs with proper packaging for international transport. Documentation services include complete customs forms, certificates of origin, and product compliance documentation. Customers appreciate the reliable delivery and professional handling of international shipments. Regional logistics coordinators provide updates and tracking information throughout the shipping process.

Product Development Innovation in Automotive Brake Technology

Continuous product development innovation in automotive brake technology drives improvements in performance, safety, and environmental compatibility. Our research and development team focuses on advanced materials, manufacturing processes, and testing methodologies for brake components. Ceramic brake pads designed for high-performance automotive safety benefit from ongoing formulation refinements and material science advancements. Metallic brake pads incorporate new alloy combinations and structural designs for enhanced durability and performance. Environmental considerations drive development of copper-reduced formulations that maintain performance while addressing regulatory requirements. Collaboration with vehicle manufacturers and industry partners ensures our products meet evolving market needs. Technical documentation provides detailed information on product innovations and performance characteristics. Customers benefit from these continuous improvements in brake technology.

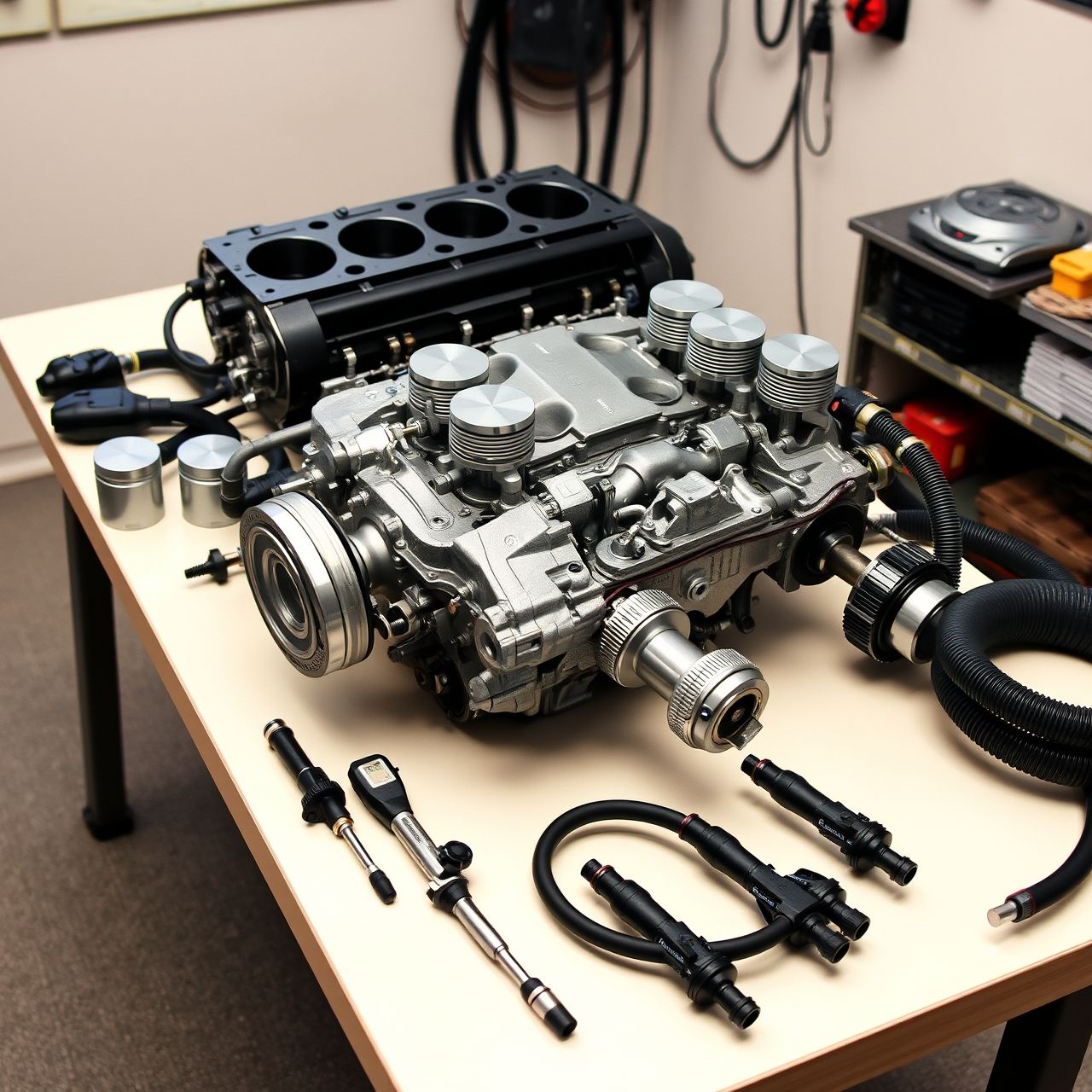

Ceramic brake pads